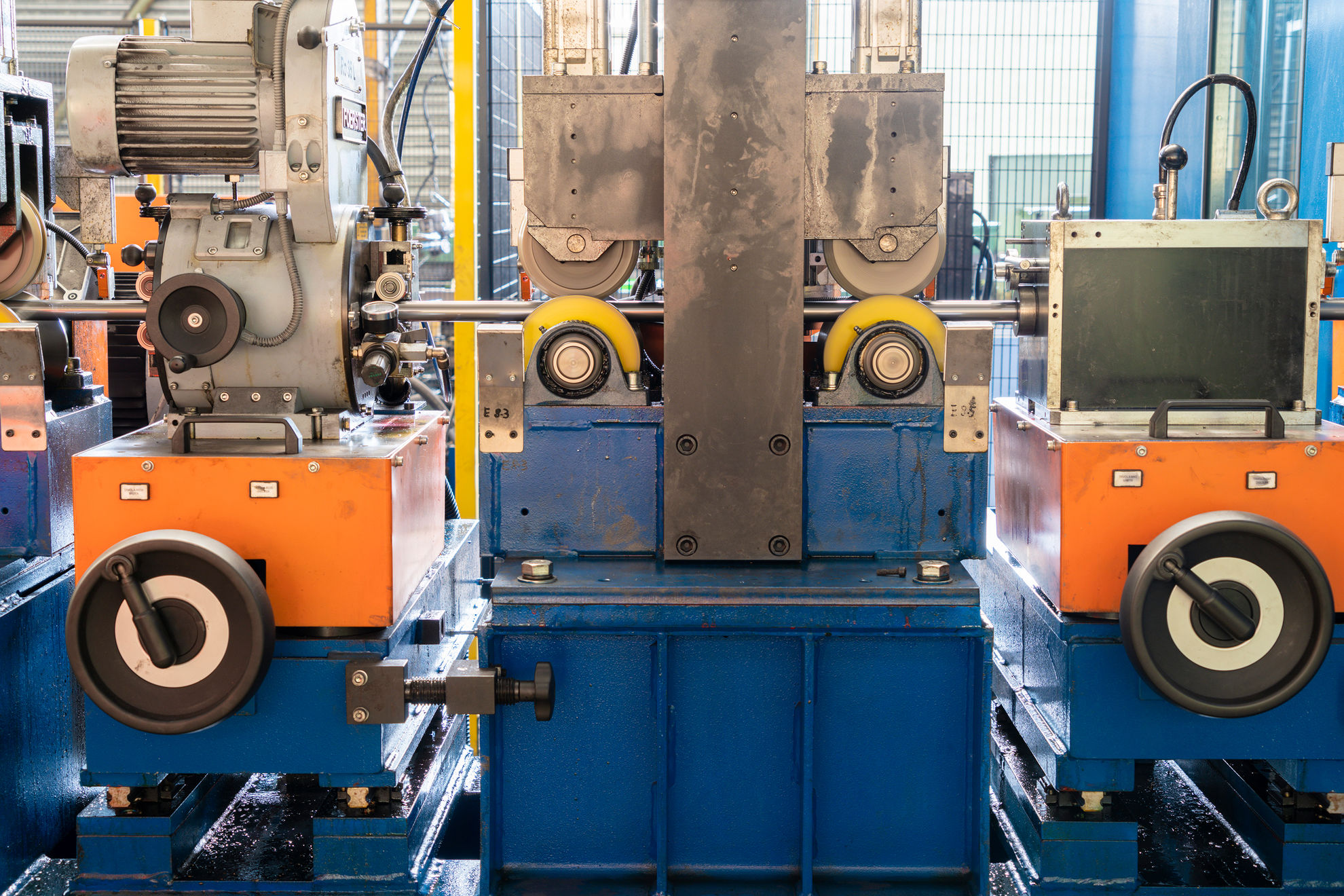

An innovative production process gives to this range of cold drawn round bars from 15 to 32 mm (to be extended up to 45 mm) special characteristics: a perfect bar end and a very high surface quality.

Controlled and perfect ends

with no waste.

The production in 6 meter bars, sawn in half in line, eliminates the typical dimensional variations of the extremities, due to the usual shearing with traditional products. This new process allows the end of the bars to have both shape and size identical to the rest of the bar.Thanks to the perfect shape of the sawn end, a small chamfer of a few millimeters is enough to prevent any problem during bar loading, avoiding waste. Even production of the first piece taken from each bar is no longer a problem. For easier bar gripping, the other end is finished with a 30° chamfer 4-6 mm deep with milling of the middle circle. Eddy current controls are guaranteed even in the first 5 centimeters of the bar, usually not controllable according to the standard, as they are performed on the 6 meter bar before cutting.

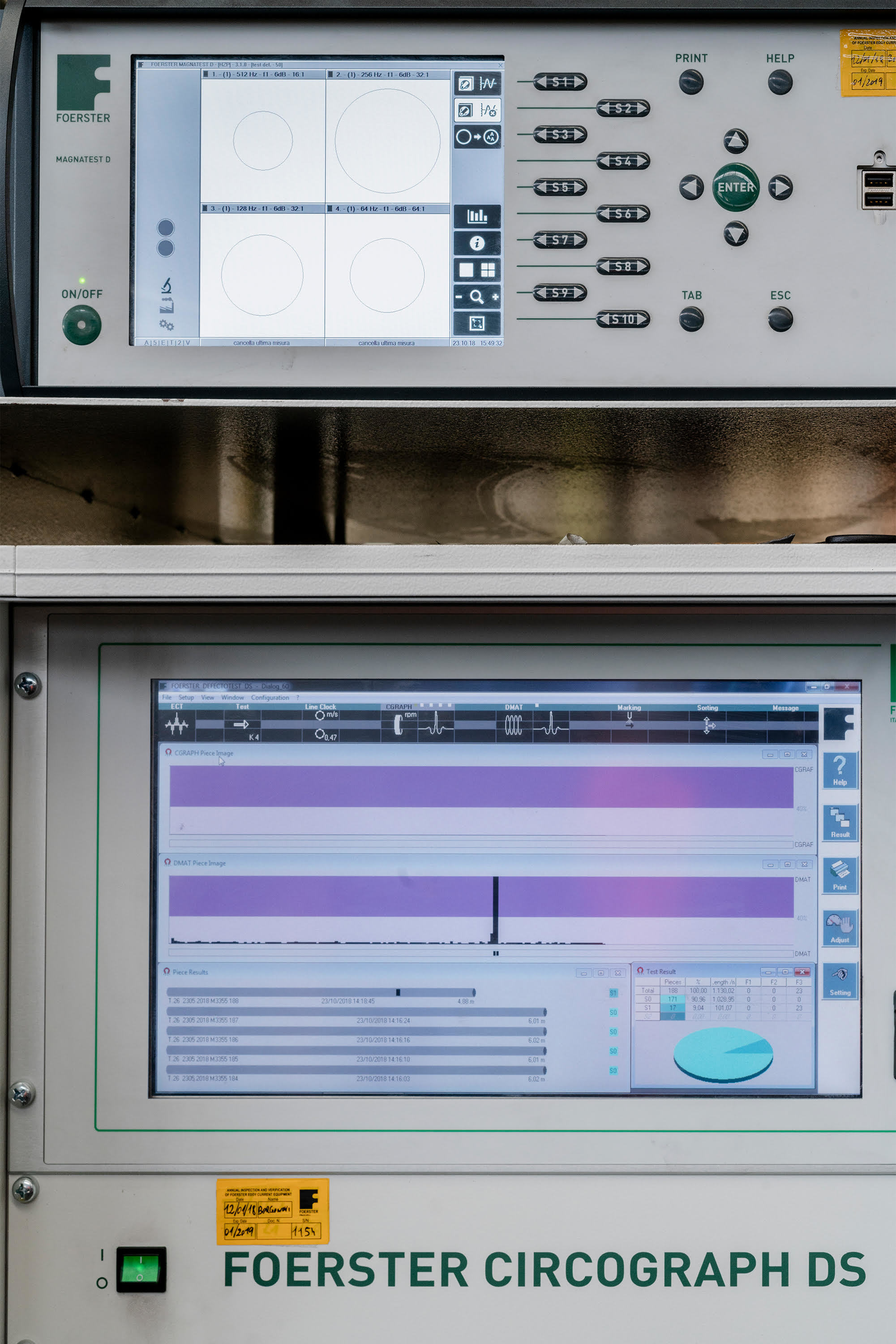

High surface quality

MAB70® can be supplied in the CIRCOGRAPH + DEFECTOMAT version, with guarantee of surface integrity much higher than Class 3. Thanks to the simultaneous use of both control devices, we are able to monitor both longitudinal defects (cracks, grooves, overlapping, etc.) and trasversal defcts (scales, pits, isolated fores, etc.). At the same time it is possible to check the first 5 centimeters of the extremity like the rest of the bar, the maximum permitted percentage of material with discontinuity depth higher than the one allowed by Class 3 is reduced more than ten fold, falling from 1% to 0.1%. This value is actually lower than the 0.2% permitted for Class 4.

Towards zero-defect

manufacturing

It is not technically possible to guarantee “zero defects” in the cold drawing process, but thanks to the MAB70® CIRCOGRAPH + DEFECTOMAT version we are very close to this outcome. This is proven by the data collected in more than two years of trials by some major producers of very delicate components for the Automotive and Hydraulic industries.